Three-step delivery

Some companies process large amounts of deliveries every day, many of which include multiple products or require special packaging. To make this efficient, a packing step is needed before shipping out products. For this, Odoo has a three step process for delivering goods.

In the default three-step delivery process, products that are part of a delivery order are picked in the warehouse according to their removal strategy, and brought to a packing zone. After the items have been packed into the different shipments in the packing zone, they are brought to an output location before being shipped. These steps can be modified if they do not fit the needs of the business.

Configuration

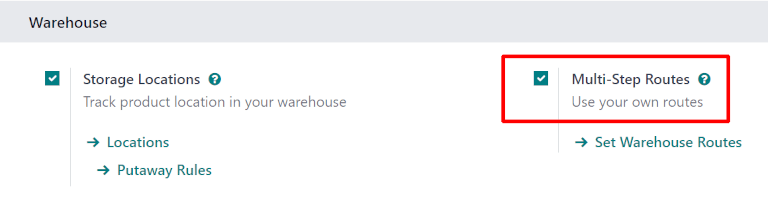

To change delivery settings from one step to three steps, make sure the Multi-Step Routes option is enabled in Inventory app ‣ Configuration ‣ Settings ‣ Warehouse. Note that activating Multi-Step Routes will also activate Storage Locations.

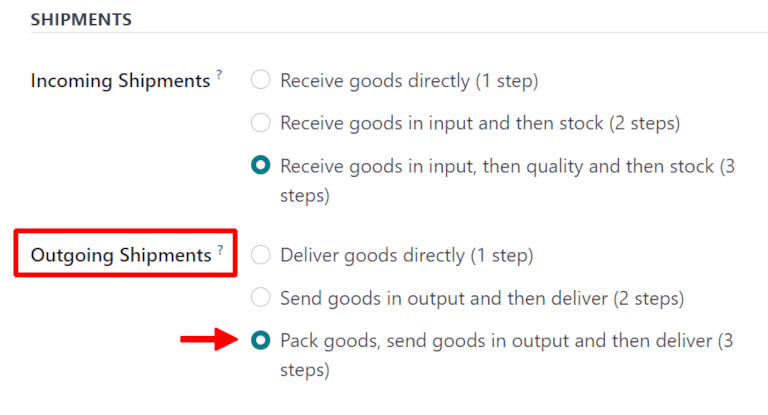

Next, the warehouse needs to be configured for three step deliveries. To do this, go to Inventory app ‣ Configuration ‣ Warehouses, and click on the warehouse to edit. Then, select Pack goods, send goods in output and then deliver (3 steps) for Outgoing Shipments.

Activating three-step receipts and deliveries creates two new internal locations: a Packing Zone (WH/Packing Zone), and Output (WH/Output). To rename these locations, go to Inventory app ‣ Configuration ‣ Locations, click on the Location to change, and update the name.

Deliver in three steps (pick + pack + ship)

Create a sales order

To create a new quote, go to Sales app ‣ Create, which reveals a blank quotation form. On the blank quotation form, select a Customer, add a storable Product, and click Confirm.

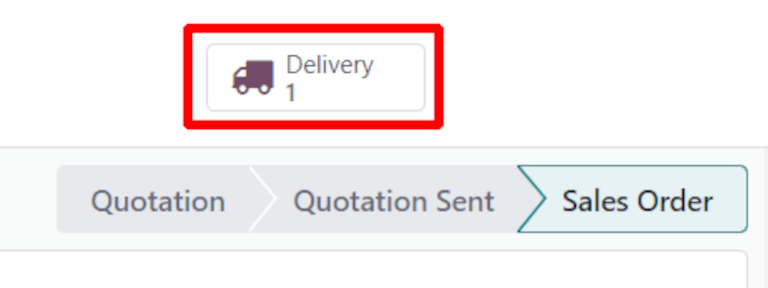

A Delivery smart button appears in the top right of the quotation form. Clicking it opens the picking order to move the ordered product from [WH/Stock] to [WH/Packing Zone].

Process a picking

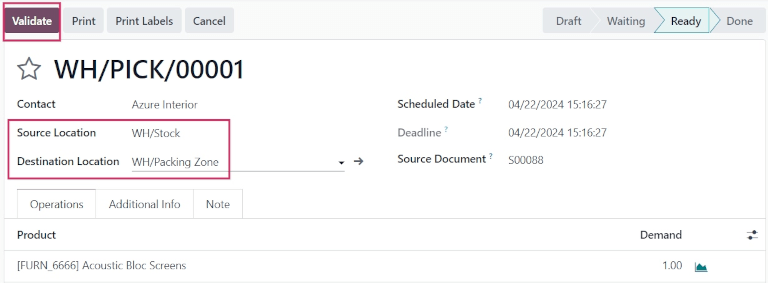

The picking order will be created once the sales order is confirmed. To view the picking, navigate to the Inventory app, and locate the Pick task card on the Inventory Overview dashboard.

Click the # To Process button, which reveals the picking order generated from the previously confirmed sales order.

Click on the picking to process. If the product is in stock, Odoo will automatically reserve the product. Click Validate to mark the picking as done, and complete the transfer to the Packing Zone.

Process a packing

After validating the picking, the packing order is ready to process. Click back to the Inventory Overview, and locate the Pack task card on the dashboard.

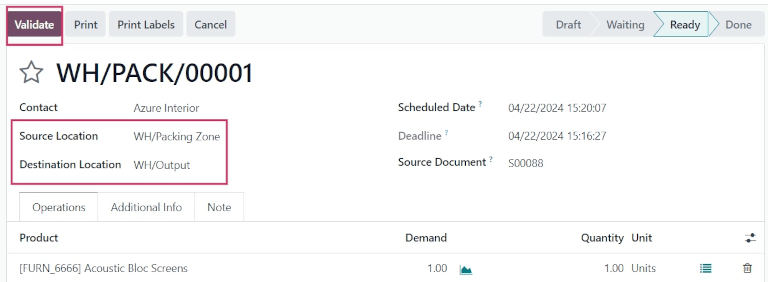

Click the # To Process button (in this case, 1 To Process). This reveals the packing order generated from the previously confirmed sales order.

Click on the packing order associated with the sales order, then click on Validate to complete the packing.

Once the packing order is validated, the product leaves the WH/Packing Zone location and moves to the WH/Output location. Then, the status of the document will change to Done.

Process a delivery

Once the packing order has been validated, the delivery order is ready to process. Navigate back to the original sales order to process the delivery by going to Sales app, and selecting the sales order created previously.

TIP

Delivery orders can also be accessed by going to Inventory app ‣ Operations ‣ Deliveries.

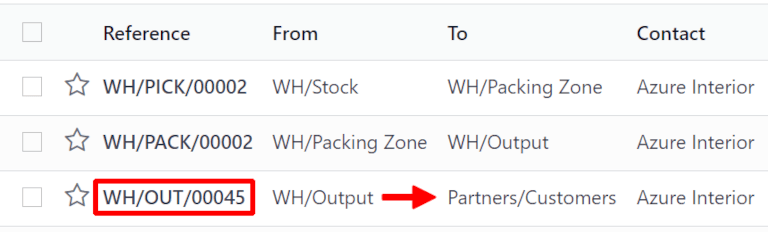

The Delivery smart button now indicates there are 3 transfers, instead of one. Clicking the Delivery smart button shows the three operations for this sales order: the picking, the packing, and the delivery.

Click the delivery (WH/OUT) transfer to open the delivery order. Then, click Validate.

Once the delivery order is validated, the product leaves the WH/Output location and moves to the Partners/Customers location. Then, the status of the document will change to Done.